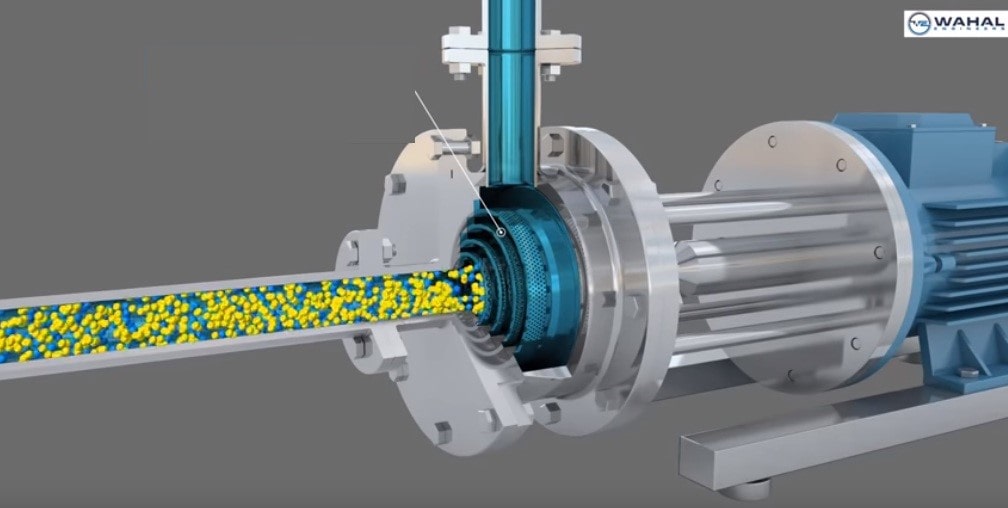

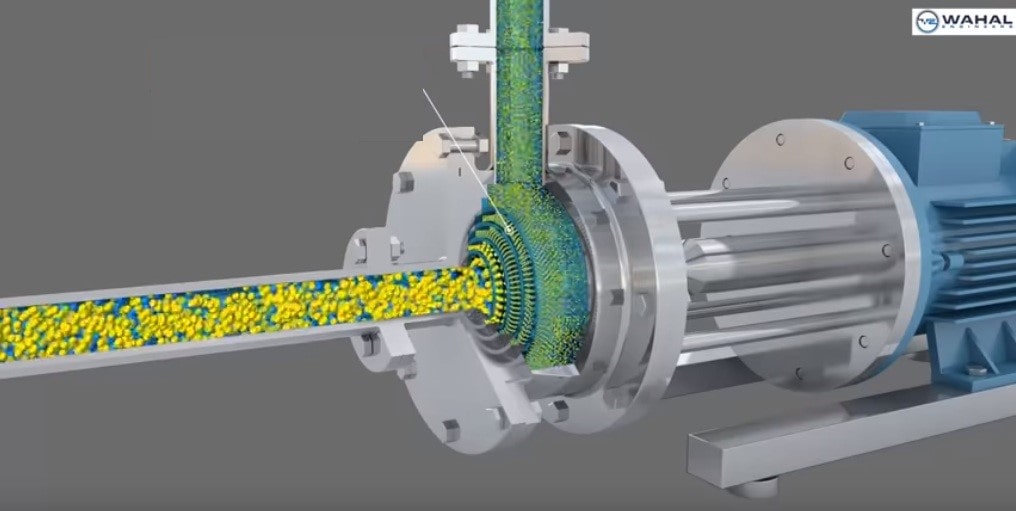

High shear inline homogenizer is to be designed for a high degree of mixing and replaces the simple agitator which is ineffective in mixing. It is applied where the requirement of high speed and pressure for the complicated process of mixing. It perform a different type of operations like emulsification, dissolution, high shear mixing, etc.

It has a self-pumping quality such that provides a centrifugal pumping action without any need of an external pump. The stators are easily changed as per particle required size for the mixing process.

Inline High Shear homogenizer is to be designed for inline high shear mixers. Which is ineffective in mixing. It performs a different type of operations mixing